Fiberglass Duct (Pipe and Fittings)

United Equipment & Fabricators offers a wide variety of fiberglass products including single-wall and double-wall duct.

![]()

Shapes

Typical shapes for filament wound construction are round, rectangular and oval. Special shapes such as triangular are also available. Engineering assistance is available for designing projects requiring non-standard construction.

Typical Duct Shapes

(Custom shapes available upon request.)

![]()

![]()

Diameter

Duct diameters are available from 2" - 144". Rectangular sizes are available as required for your projects. ![]()

Wall Thickness

Duct wall thickness ranges from 1/8" to 1" (increasing in increments of 1/16"). Other wall thicknesses are available for abnormal burial depths or other special loading requirements. Standard ductwork is furnished with the following minimum wall thickness:

| Diameter | Wall Thickness |

| 2" to 20" | .125 inches |

| 21" to 36" | .187 inches |

| 37" to 60" | .250 inches |

Lengths

Standard length is 10'-0". Lengths up to 50 feet are available.

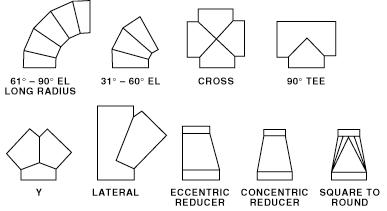

Fittings

Standard fittings include:

- Elbows

- Tees

- Laterals

- Y's

- Reducers

- Dampers

- Register Boxes

- Square to Rounds

- Crosses

- Flanges

- Blastgates

- Access Door

- Stacks

- Caps

- Hoods

Typical Duct Fittings

(Custom fittings available upon request)

![]()

![]()

Colors

A wide range of colors are available for overhead exposed applications. Please contact United Equipment for a color chart.

Specifications

Please contact United Equipment for detailed specifications on our fiberglass duct.

Installation & Joining

United Equipment's FRP duct is easy to configure and install. Our ducts can be installed overhead or directly buried into a pea gravel backfilled trench without concrete encasement.

Duct supports/hangers should be per recognized standards such as SMACNA or ASTM D-3952. In general, spacing is 8-12 feet dependent upon diameter and loading factors. Supports should be a minimum 120 degrees of diameter. Particular attention should be given to properly design supports and hangers to avoid point loading.

![]()

![]()

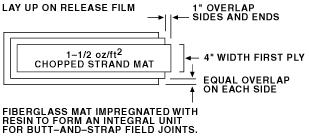

Field Wet Lay-Up Joint Instructions (see Figures 3, 4, & 5)

This requires joining duct and/or fittings with resin and fiberglass mat. See separate Welding Procedures for complete details.

Wet field joints shall be a minimum four (4) inches in width and at least the same thickness as adjoining duct wall. Butted sections may be "tabbed/hot patched" to hold alignment until a complete joint can be made.

NOTE:

LEAK TEST THE SYSTEM BEFORE PLACING INTO SERVICE.

![]()

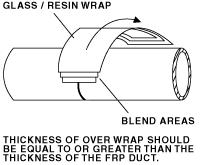

Bell and Spigot Connection (see Figures 3, 4, & 5)

This requires joining duct and/or fittings with resin and fiberglass mat and additionally filling the bell gap with putty. See separate Welding Procedures for complete details.

Figure 3

Preparation of Strapping

(Complete instructions available upon request.)

Figure 4

Application of Strapping

(Complete instructions available upon request.)

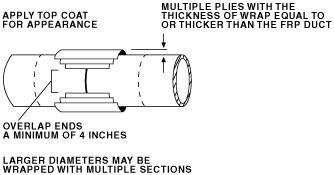

Figure 5

Butt-and-Strap End-to-End Joint

(Complete instructions available upon request.)

Flanged Connection

Flanges are furnished undrilled for field drilling to match equipment. Flanges are furnished factory mounted or as loose stub flanges. Flange connections should be gasketed per architect's/engineer's specification.

Previous page: Fiberglass Dampers (Square & Round)

Next page: Fiberglass / Plastic Grating & Structural Shapes